Dumpster Rentals in Atlanta, GA

Sat: 8 am - 5 pm EST

Rent a Dumpster Near You to Keep Spending In Check

Don’t let cleanup costs drain your budget. Get a cheap dumpster rental from us instead. With your rental period, delivery and pickup bundled into one low rate, it’s easy to save on any Atlanta project.

With us, you'll enjoy:

- Speedy deliveries and pickups.

- A wide range of dumpster rental sizes.

- Expert service you can trust.

Household & Construction Dumpsters

These roll off dumpsters can be used for common household and commercial projects, including home cleanouts, remodeling, general construction and demolition.

50-70 Trash Bags

- Attic cleanouts

- Light demolition

- Concrete disposal

65-85 Trash Bags

- Basement cleanouts

- Deck and patio projects

- Asphalt disposal

80-100 Trash Bags

- Bathroom remodels

- Roofing repairs

- Festivals

110-130 Trash Bags

- Partial home cleanouts

- General construction

- Roofing projects

170-190 Trash Bags

- Office cleanouts

- Home additions

- Decluttering before a move

230-250 Trash Bags

- Full home cleanouts

- Complete home remodel

- Commercial renovations

*Disclaimer: All dumpster dimensions may vary slightly but volume is accurate. Prices and availability are subject to change without notice. Capacity estimates are based on the volume of a 33 gallon trash bag.

Discover Atlanta Dumpster Rental Service That’s as Sweet as a Peach

Does the thought of junk removal leave you with a bad taste in your mouth? There’s nothing sour about working with us. Remodeling your restaurant along Peachtree Street? Renovating your home near the Georgia Aquarium? Renting a dumpster will make your job as smooth as honey. Tell our team about your job and we’ll recommend the right roll off dumpster for the materials you’re tossing. Then, we’ll deliver your bin where you need it so you can clean up at your own pace. Request a pickup online when you’re done and we’ll handle the rest. Dial 404-965-2996 to begin.

Why We’re the Right Choice

Budget Dumpster is your hassle-free waste removal solution. From our flat-rate dumpster rental prices to our expert customer service, we streamline the process of renting a dumpster. You can toss all kinds of debris into our roll off containers, from home clutter and drywall to yard waste and concrete. Whether you’re a first-time renter or a seasoned pro, working with us helps you get your job done faster.

What Materials Can Our Dumpster Rentals Take?

Accepted Household Debris

- household junk

- carpet

- flooring

- appliances

- electronics

- furniture

- mattresses & box springs

- fixtures

- yard waste

- stumps

Accepted Construction and Heavy Debris

- construction debris

- wood & drywall

- roofing materials

- concrete

- dirt

*Please call your sales representative to learn more about disposing of specific materials, as well as any items we cannot accept.

by Donna Anastasia

April 24

Great company

Read moreby Mike P

April 24

Great customer service on time and great driver

Read moreby Regenia Lewis

April 23

Very professional & reliable

Read moreFrequently Asked Questions

Do I need a permit for my Atlanta dumpster rental?

If we drop off your bin on private property, like your driveway or a construction site, you don’t need a permit. But if you want us to deliver your roll off container to the street, sidewalk or another piece of public property, you will need a Right-of-Way Permit from the city of Atlanta before delivery. Reach out to our team if you have questions about permits or dumpster placement.

How much is it to rent a dumpster?

Our roll off dumpster rental prices are budget-friendly and based on your project needs. Location, dumpster size, debris type, debris weight and rental period all affect your dumpster rental costs. When you call our team for a personalized quote, we’ll find the best price for your job. You can also get a quote online now.

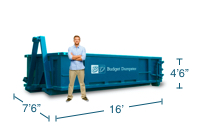

What size roll off dumpster do I need?

The dumpster size you need depends on the scope of your project and the type of debris you’re tossing. A 10 yard dumpster is ideal for a small garage cleanout while a 40 yard container provides the space needed for a large renovation project. We offer a range of dumpster rental sizes in between to fit projects of any size. Contact us for a customized recommendation.

How It Works

1. Choose a size and delivery spot. We require 60 feet of space in a straight line and 23 feet of vertical clearance.

2. Prepare for delivery. Remove any vehicles, materials or low-hanging obstacles to ensure we can deliver your dumpster and to avoid a trip fee.

3. Fill up your dumpster. Remember to keep your included weight limit in mind to prevent overage fees.

4. Schedule your pickup. To ensure pickup and avoid a trip fee, your dumpster must be accessible and only contain approved debris piled no higher than the sidewalls.

Looking for a dumpster closer to home? Find your location below:

Become a Hauling Partner

Want more business? Work with us and you can sell more dumpsters without the added overhead. Learn more about partnering with Budget Dumpster.