Dumpster Rentals in Detroit, MI

Sat: 8 am - 5 pm EST

Rent a Dumpster for a Low Price

We offer speedy service and flat rates that bundle your dumpster rental period, delivery and pickup. So, no matter where you’re cleaning up in Detroit, you can keep your budget on track.

With us, you'll enjoy:

- A variety of roll off container sizes.

- Fast scheduling, delivery and pickup.

- Expert support from our friendly team.

Household & Construction Dumpsters

These roll off dumpsters can be used for common household and commercial projects, including home cleanouts, remodeling, general construction and demolition.

50-70 Trash Bags

- Attic cleanouts

- Light demolition

- Concrete disposal

80-100 Trash Bags

- Bathroom remodels

- Roofing repairs

- Festivals

110-130 Trash Bags

- Partial home cleanouts

- General construction

- Roofing projects

170-190 Trash Bags

- Office cleanouts

- Home additions

- Decluttering before a move

230-250 Trash Bags

- Full home cleanouts

- Complete home remodel

- Commercial renovations

*Disclaimer: All dumpster dimensions may vary slightly but volume is accurate. Prices and availability are subject to change without notice. Capacity estimates are based on the volume of a 33 gallon trash bag.

How It Works

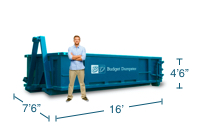

1. Choose a size and delivery spot. We require 60 feet of space in a straight line and 23 feet of vertical clearance.

2. Prepare for delivery. Remove any vehicles, materials or low-hanging obstacles to ensure we can deliver your dumpster and to avoid a trip fee.

3. Fill up your dumpster. Remember to keep your included weight limit in mind to prevent overage fees.

4. Schedule your pickup. To ensure pickup and avoid a trip fee, your dumpster must be accessible and only contain approved debris piled no higher than the sidewalls.

Tackle Any Cleanup With a Detroit Dumpster Rental

Junk removal in Motor City is stress-free with Budget Dumpster by your side. We’ll recommend the right roll off dumpster for your cleanup, whether you’re a DIYer completing a weekend project or a contractor on a long-term job. Our dumpsters can hold trash from Noel Night in Midtown and clutter from your home in Sherwood Forest. Renovating a vacant building in Piety Hill? It’ll go much faster with a roll off container. We’ll drop off your bin where it’s convenient. When you’re finished loading, schedule a pickup online, and we’ll haul away the mess. Call 313-989-0320 today.

Why Choose Budget Dumpster?

Our service is customized to your project, including flexible dumpster rental periods so you can work at your own pace. Need more time to finish your project? For a flat daily rate, you can usually keep your roll off container for an extra day or two. Have an upcoming project already on the schedule? We’ll set up delivery weeks or months ahead of time so you get the dumpster you need right on time. Just tell us your need, and we’ll do our best to accommodate it.

What Materials Can Our Dumpster Rentals Take?

Accepted Household Debris

- household junk

- carpet

- flooring

- appliances

- electronics

- furniture

- mattresses & box springs

- fixtures

- yard waste

Accepted Construction and Heavy Debris

- construction debris

- wood & drywall

- roofing materials

*Please call your sales representative to learn more about disposing of specific materials, as well as any items we cannot accept

by Janet

April 18

Easy and hassel free service

Read moreby Robert Hall?

April 18

Delivery and pickup were great

Read moreby Satisfied Customer

April 18

Great service.

Read moreFrequently Asked Questions

When I rent a dumpster, when will it arrive?

When you order a dumpster from our team, we'll schedule delivery on your timeline. Depending on availability, we can usually drop off your dumpster rental in one to three business days. You don't have to be there when our truck arrives. Just make sure the delivery area is accessible and clear before we get there. This means moving cars, equipment and other potential obstacles out of the way. Planning to keep your roll off container in the street? Get a Right of Way Permit from Detroit's Public Works Department in advance. Reach out for more preparation tips.

How much does it cost to rent a dumpster in Detroit?

Roll off dumpster rental prices typically range from $217 to $1,040. The price for your rental depends on your location, dumpster size, debris type, debris weight and rental period. You can get a personalized quote online now. Still unsure about bin sizes or dumpster rental prices? Give us a call. We’ll answer those questions and more.

Should I cover my dumpster rental if it rains or snows?

If you’re expecting bad weather during your cleanup, secure a tarp over your roll off container with bungee cords or tie-down straps. This keeps excess moisture out of your dumpster, which could add weight to your debris and put you over your quoted weight limit. You should be especially careful if you're tossing dirt, upholstered furniture and other absorbent materials. Need help preparing your roll off dumpster for a storm? Give us a call.

Looking for a dumpster closer to home? Find your location below:

Become a Hauling Partner

Want more business? Work with us and you can sell more dumpsters without the added overhead. Learn more about partnering with Budget Dumpster.