How to Dispose of a Mattress

The Complete Mattress Disposal Guide

Wondering how to get rid of that old mattress? Despite being bulky and heavy, there are several convenient ways to dispose of mattresses, including renting a dumpster, donating and recycling it.

A gently-used mattress can be donated, but if yours is old and worn out, you’ll need to throw it away. We’ve compiled the best mattress and box spring disposal options so you can find the most efficient method for your needs.

Mattress Disposal Options

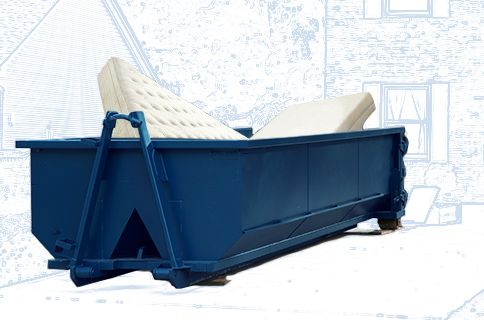

1. Rent a Roll Off Dumpster

If you’re getting rid of an old mattress as part of a home cleanout, renting a dumpster is a great option for disposing of all your junk at once. With a dumpster rental on your property, you can easily carry your mattress, box spring and other materials into the container and have it all hauled away when you’re done cleaning up. Budget Dumpster’s services are a cost-effective junk removal option, and you can keep your dumpster on-site for a weekend or longer and work at your own pace.

Benefits | Things to Consider |

|---|---|

|

|

|

|

| |

|

Ready to Rent a Dumpster?

2. Check With Your Local Trash Collection Service

In some areas, municipal curbside services will remove mattresses during weekly collection days or on specified bulk pickup days. Reach out to your town’s trash and recycling service to see if this is an option in your area and how items should be prepared for pickup.

Benefits | Things to Consider |

|---|---|

|

|

|

|

|

|

|

3. Hire a Junk Removal Company

Junk removal services are another option for mattress removal. The company will come to your location and haul away your mattress and other junk in their truck. However, you won't get a quote for this service until they see how much space your items take up in the truck. You will also need to be on-site and work within the two-hour window they provide.

Benefits | Things to Consider |

|---|---|

|

|

|

|

|

How Much Does Mattress Removal Cost?

Mattress removal costs can range from $10 up to $700, depending on the number and size of the mattresses you’re getting rid of, as well as the service you choose and your location.

The average cost of a junk hauling service is $297, which usually covers 9 cubic yards, or 3 pickup truck loads, of junk.

If you are getting rid of multiple mattresses as well as other household junk, a dumpster rental will be the most economical option. The average cost of a 20 yard dumpster rental is $447, which includes more than double that amount of debris and can fit multiple mattresses and box springs.

When you rent a dumpster for mattress and box spring disposal, you can choose a container size that fits the amount of trash you have. And you can keep your dumpster on-site until you’ve finished cleaning up, making it the timelier and more efficient disposal option.

Costs of Various Mattress Disposal Options

Disposal Option | Cost |

|---|---|

| |

| |

| Mattress disposal costs between $10 - $50 per item at most landfills. This does not include the cost of a truck rental, gas and time spent hauling the materials. |

| Mattress recycling costs between $20 - $40 per item in most areas. |

Mattress Recycling Options

Looking to give your old mattress new life? There are a few options for mattress recycling that will keep it out of the landfill and reduce your carbon footprint.

1. Consult the Mattress Recycling Council

In California, Connecticut and Rhode Island, you are legally required to recycle mattresses through a program administered by the Mattress Recycling Council, which costs between $10 and $17 per mattress. To get rid of your mattress in these locations, you will need to have your mattress removed by the retailer when your new one arrives or deliver it to a certified recycling facility yourself.

2. Find a Recycling Location Near You

There are also more than 20 other states with at least one mattress recycling facility. Use PlushBeds' recycling guide to find a facility near you. Fees may apply.

3. Ask About Retailer Take-Back Services

If you’re in the process of buying a new mattress, ask the retailer if they will remove and recycle your old mattress when delivering the new one. This common option is convenient, but may include a small fee.

Mattress Donation Options

Even if you are getting a new one, you may not have to throw your old mattress away if it doesn’t show much wear. If the mattress is less than 5 to 7 years old and does not have any rips, stains, frayed edges or obvious signs of compression, it could still be useful to someone else.

1. Find It a New Home

Check with relatives and friends who may be looking for an extra mattress, or simply want to replace their current one. As long your as mattress is in good shape, this is a great way to keep it out of the landfill.

2. Donate Your Mattress to a Local Nonprofit

There are several nonprofit organizations and institutions that would gladly take your gently-used mattress. The groups below generally accept mattress donations, though local policies may differ.

These organizations usually offer mattress pickup:

- Salvation Army (also allows for drop-off)

- Furniture Bank Association of America locations (also allows for drop-off)

These organizations typically require mattress drop-off:

- Places of worship

- Local charities and shelters

Frequently Asked Questions About Mattress Disposal

Can mattresses be put in a dumpster where I live?

If you are renting a dumpster for a home cleanup or specific project, contact our team to learn about accepted materials and mattress disposal rules in your area beforehand. There may be an additional charge for each mattress or box spring you are disposing of due to local fees charged by the landfill or transfer station.

Can I mix other debris with mattresses in a dumpster rental?

Yes, when you rent a dumpster, you can place any old mattresses and household junk inside the same container, as long as none of the items are prohibited in your area and you do not overfill the dumpster.

Are there any fees for disposing of a mattress in a dumpster?

In some areas, there are fees associated with getting rid of a mattress. Mattress disposal charges apply when the local landfill or transfer station must break down or recycle the mattress. These charges come directly from the local facility and will apply whether you’re using a dumpster rental, curbside pickup or landfill drop-off.

Can I break apart my mattress and throw away the accepted materials?

You can break down your mattress yourself to make disposing of it easier, though you may still be subject to any associated disposal fees. Breaking down the mattress may reduce the amount of space it takes up in your dumpster rental or junk removal truck.

Can I dispose of box springs in the same way as a mattress?

Depending on the service you choose, you should be able to dispose of an old mattress and a box spring in the same way. If you rent a dumpster, you can throw both in the bin. If you are scheduling removal with a junk hauling service, you may end up paying more to have both removed.